Transformers: Why They’re Important

Transformers are used to transfer alternating current from one circuit to another. Their practicality comes from the ability to change electric voltage without altering frequency. What that means is they’re so key to electronics today, you’ll find them in virtually every household appliance and in the power supply to any device. On a larger scale, all industrial equipment and power grids use them to distribute and regulate power.

Transformers are prized for increasing power safety and efficiency in a number of ways: stabilizing voltage fluctuations; raising or lowering voltage levels; providing isolation. Their versatility enables them to operate from frequencies of one Hertz to Gigahertz and with power levels from micro-Amps to mega Amps. This, combined with voltage, power, frequency and mechanical requirements, means the possibilities for transformer designs are infinite.

In this guide, we’ll discuss how to navigate through those myriad possibilities and examine the pros and cons of custom versus standard transformers.

Standard and Custom

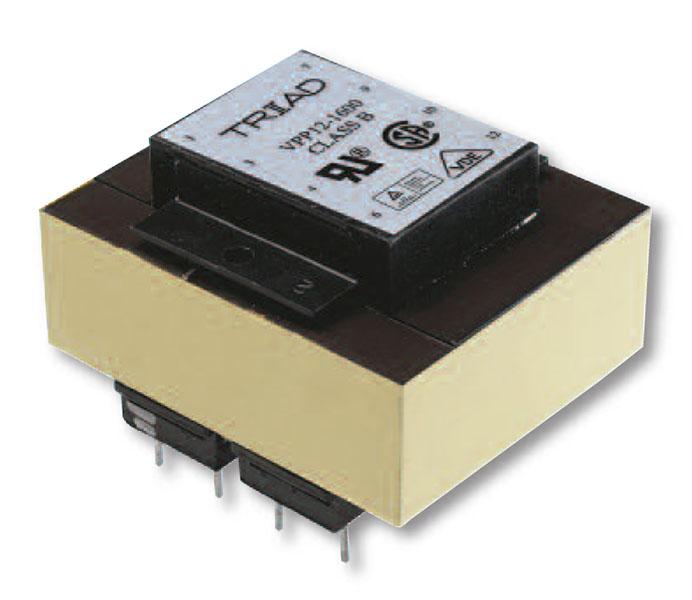

Over the years of electrical development, some common requirements have emerged allowing transformer manufacturers to develop standardized products (off the shelf) covering a wide range of applications. For example, a simple transformer stepping down voltage from 240VAC to 120VAC, operating at 50Hz-60Hz has worldwide applications for most electrical equipment. Naturally almost every manufacturer has off the shelf products to satisfy this requirement and others like it.

However, there are also many unique projects and applications being created that require uncommon input or output voltages presenting problems or opportunities to be solved with appropriate understanding by a good transformer manufacturing team. In other words, a custom design solution.

This guide is designed to help you determine the benefits and ideal situations for employing standard or custom transformers.

Triad Magnetics is a trusted source for standard and custom magnetics solutions worldwide. To learn more about why you should partner with Triad Magnetics

Contact us todayThe Four Main Considerations When Choosing Between a Standard or Custom Transformer

There are factors to consider when determining the suitability of a transformer solution.

The following are key points in assessing your needs.

-

1. Cost

1 Cost

Learn More

-

2. Timeline

2 Timeline

Learn More

-

3. Performance Expectations

3 Performance Expectations

Learn More

-

4. Application Specifics

4 Application Specifics

Learn More

How To Know If You Need a Custom Transformer

Many customers don’t know if they need a custom or standard transformer. Using key words and performance parameters to search the internet may help to identify manufacturers with standard parts that could work for you.

To make this easier, Triad’s website includes a parametric search that is a simple first step to finding a specific transformer. If the search doesn’t return any results, however, you may need a custom transformer. Our engineering team is there to assist you and if we aren’t able to meet your needs, will do our best to refer you to a manufacturer that can.

Custom transformer design can be complex. It is critical to evaluate the performance requirements of your application to determine whether a standard transformer will fulfill its needs. The time required to market and lower upfront investments are the key points of concern for people who choose standard products. If, however, standard appears not to be the best option, it is better to invest the time and money into designing a custom transformer that will achieve peak performance based on your priorities. We’re here to help make that as simple and seamless as possible.

ENGINEERING

MANUFACTURING

PERFORMANCE

TIME

MONEY

Finding A Quality Custom Transformer Manufacturer

Whether sourcing a standard or custom transformer, it’s important to partner with a company committed to the quality and performance of its products. Additionally, there are a few factors to consider which we at Triad believe are important facets of the working relationship we provide.

-

Engineering Support

Engineering Support

Learn MoreConsider whether your manufacturer outsources engineering support services or handles them in house. Adequate engineering support is critical. You want to be sure your custom transformers are built to the correct specifications, and you receive appropriate troubleshooting support for your standard ones.

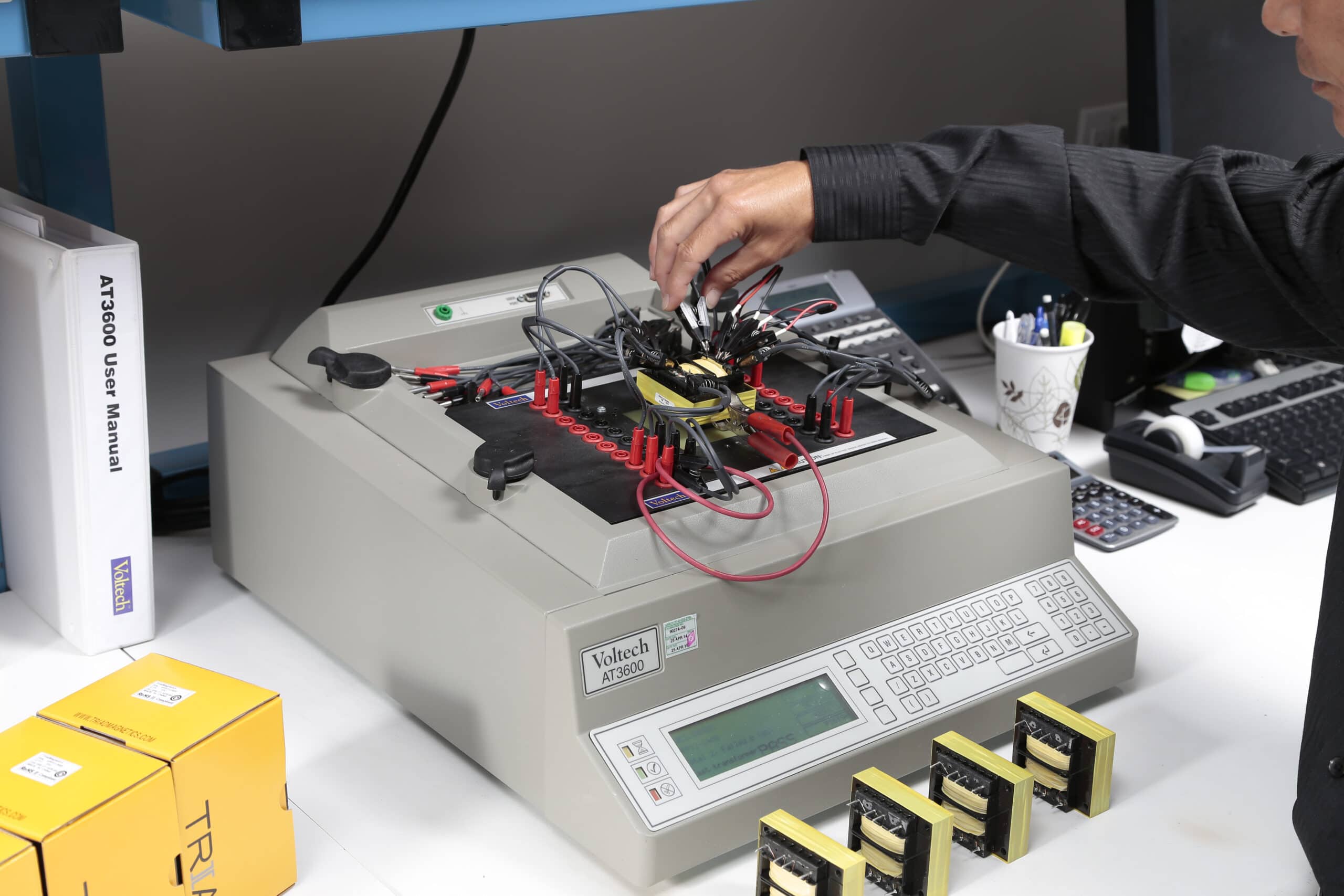

Some manufacturers depend on offshore subcontractors for design support. This can lead to delays, misunderstandings and less than optimal solutions. Our design and engineering team is in house and responds directly to any specific customer needs. We are there from product concept to delivery.

-

Product Capability

Product Capability

Learn MoreProduct performance is an essential factor in choosing a transformer manufacturer. Ask a potential manufacturer if they have produced anything similar to what you’re seeking.

Having designed and produced a wide range of transformer types over the years, our considerable experience and knowledge means we can meet most any transformer need. We’ve been working in this field for decades. What’s more, if on the off chance we aren’t the best solution, we’ll point you to whoever we think might be.

-

Production Capability

Production Capability

Learn MoreFlexibility in production is a worthwhile consideration in choosing a manufacturer. Working with one that focuses on high volume production may seem like a good idea, but can present challenges during production, ramp up and end of life. Similarly, working with a manufacturer with limited capacity can restrict your growth.

We have manufacturing capabilities for both low and high volume. We have no trouble scaling up or down depending on demand, seasonality or other issues. We are readily able to assist with your varying production logistics, ensuring you receive the goods you require at the appropriate time.

-

Reputation

Reputation

Learn MoreCheck the reputation of your potential transformer manufacturer. Their knowledge and ability to develop a product should match your quality criteria, whether it be a standard or custom transformer.

Quality is at the heart of what we do. We review and enhance our products and operations regularly. For 80 years, we have ensured consistently meeting and typically exceeding our customers’ expectations with our solutions, performance and service.

Why Triad

We hope we’ve made a case for our knowledge, understanding and capabilities in the design and manufacture of transformers, both standard and custom. With 80 years in the field and full compliance with certifications like ISO 9001: 2015, as well as a reputation for congenial service and delivery, we’d like you to know we’re happy to discuss whatever your best options to proceed might be. If you have a design project waiting to begin, or if you’d like some consultation in the process, please feel free to Contact us.