Triad Magnetics is the go-to source for high-volume manufacturing of custom-designed switching power transformers. We supply custom transformers built to exact standards and in large quantities for companies across North America. Here, we describe one case in which our transformers enhanced the way a meter-manufacturing company builds their products.

Wanted: Compact Transformers with Excellent Isolation

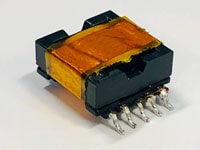

Our customer needed a custom high-frequency switching power transformer that incorporated a small, low profile form factor (0.61” × 0.63” × 0.32”) and tight tolerance coplanarity (±0.004) in large quantities (1.6 million units per year). Despite its small size, the transformer had to insulate against dielectric strengths of at least 1,500VAC. As such, we had to achieve perfect electric isolation between the copper shield and magnet wire while keeping manufacturing yields as close to 100% as possible. Triad’s engineering, production, sales and fulfillment teams worked closely with the client to develop a unique custom solution tailored to their needs.

Our customer needed a custom high-frequency switching power transformer that incorporated a small, low profile form factor (0.61” × 0.63” × 0.32”) and tight tolerance coplanarity (±0.004) in large quantities (1.6 million units per year). Despite its small size, the transformer had to insulate against dielectric strengths of at least 1,500VAC. As such, we had to achieve perfect electric isolation between the copper shield and magnet wire while keeping manufacturing yields as close to 100% as possible. Triad’s engineering, production, sales and fulfillment teams worked closely with the client to develop a unique custom solution tailored to their needs.

Triad’s Solution

To design this custom part, we used a number of processes across our facilities, including precision CNC gapping, laser drilling, and soldering. We utilized specialized winding equipment for this transformer, comprised of a precision-gapped ferrite core, hi-temp magnet wire, and copper shield, all insulated with hi-temp Mylar tape to meet the minimum dielectric strength requirements. Combining all of these materials into such a small package was a significant challenge. Developing new and consistent production processes was particularly important in order to ensure the transformers’ low profile.

To design this custom part, we used a number of processes across our facilities, including precision CNC gapping, laser drilling, and soldering. We utilized specialized winding equipment for this transformer, comprised of a precision-gapped ferrite core, hi-temp magnet wire, and copper shield, all insulated with hi-temp Mylar tape to meet the minimum dielectric strength requirements. Combining all of these materials into such a small package was a significant challenge. Developing new and consistent production processes was particularly important in order to ensure the transformers’ low profile.

We tested pilot products using Hipot for the specified dielectric strength. We also performed inductance testing, direct current resistance (DCR) assessment, and coplanarity evaluations to make sure that the transformers’ performance met or exceeded our client’s requirements. These tests were incorporated into our quality control to ensure that the production parts measured up to the strict specifications.

Working with Triad

This meter manufacturing firm went on to achieve great success with our custom transformers, listing us as their Preferred Supplier on their Quarterly Business Review Scorecard. It’s a testament to Triad’s design expertise and manufacturing acumen that customers keep coming back to us year after year.

Case Study Product Specifications :

Below is a complete list of specs for the finished custom transformer.

- Project Name

On-board Power Supply for electric meter

- Equipment Used to Manufacture Part

Multi-head auto-winding, gapping and auto-testing equipment

- Overall Part Dimensions

0.61” × 0.63” × 0.32”

- Tightest Tolerances

±0.004 (coplanarity)

- Material Used

Magnet wire, ferrite core, insulation and copper shield

- Material Finish

Mylar tape

- Target Industry

Power utility (Meter manufacturing)

- In-Process Testing/Inspections Performed

Inductance, DCR, Hipot, and coplanarity

- Delivery Lead Times

14–16 weeks

- Volume

1.6 MM

Contact Triad for your next Project Solution

We maintain high standards of quality for our products, and we work to achieve fast turnaround times while keeping our prices down. In addition to transformers, we design world-class power supplies and inductors.

To learn more about our power transformer capabilities or our other product offerings, contact our team today.